One minute to learn about batteries in energy storage systems

We often see about megawatt-level (MW) or even hundred-megawatt-level (100MW) electrochemical energy storage power stations, how are the batteries of these storage power stations composed? How did it get to such a large scale? Let’s have a quick chat.

The smallest cell, which is also called a cell, consists of electrochemical devices with electrodes and electrolytes that store obtained electrical energy in the form of chemical energy and convert the chemical energy into electrical energy. For example, we often come into contact with batteries No. 5 and No. 7 used in various small appliances or remote controls. Another example is the 18650 battery used by Tesla cars, which has a diameter of 18mm and a length of 65mm.

Batteries in Energy Storage Power Stations

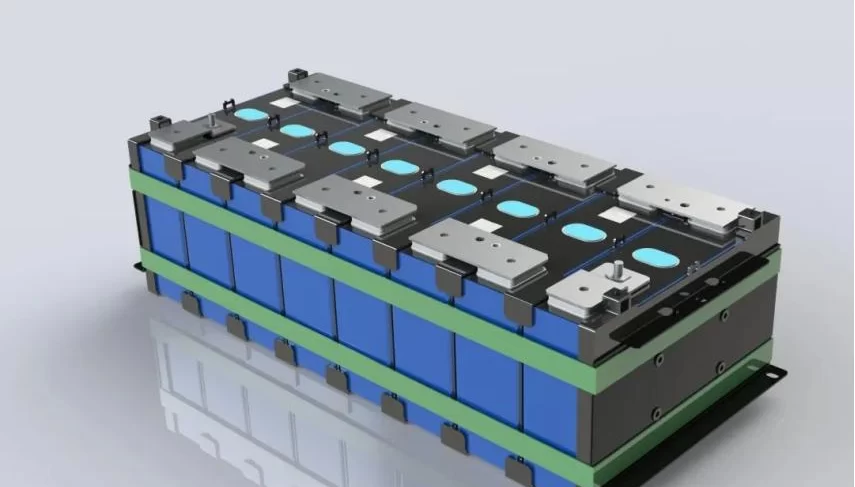

The batteries used in energy storage power stations are not the batteries, but lithium iron phosphate batteries that are generally square in shape, with a voltage of 3.2V and capacity from tens of amps to hundreds of amps. For example, the following lithium battery in Shanghai Huijue weighs about a few kilograms. The capacity of battery cells is developing in the direction of increasing, and at present, large-scale energy storage stations also tend to use batteries with larger single capacity, such as 280Ah, 320Ah and so on. A certain number of individual the batteries are connected electrically in a specified way, either in series or in parallel, to form a battery module or pack. Since after series or parallel, the voltage or capacity of the battery can be improved, the general voltage or capacity of the battery module is higher than that of a single battery. These are one or more battery clusters connected to the same power conversion system that forms a collection of the batteries that can control, as a whole, the power input and output. A number of battery modules with a certain electrical connection (series or parallel) and circuit equipment (monitoring and protection circuits, electrical and communication interfaces and thermal management devices, etc.) can be integrated into a bigger battery capacity, namely a cluster of batteries (battery cluster or Rack). Large energy storage battery systems generally include: battery management system (BMS) electrical connection components, structural support components, cooling systems, fire protection systems. The BMS collects, analyzes, and judges the data of the whole battery system, with perfect event recording and historical data storage functions. And it can set the operating parameter and charge/discharge of the whole battery system. Inside the battery, there is a cluster management unit for the battery, guaranteeing through monitoring and control the normal working and performance of each cluster of batteries. The battery management unit shall monitor and balance the battery module to ensure the consistency of each single battery in the battery module and extend the service life of the battery.